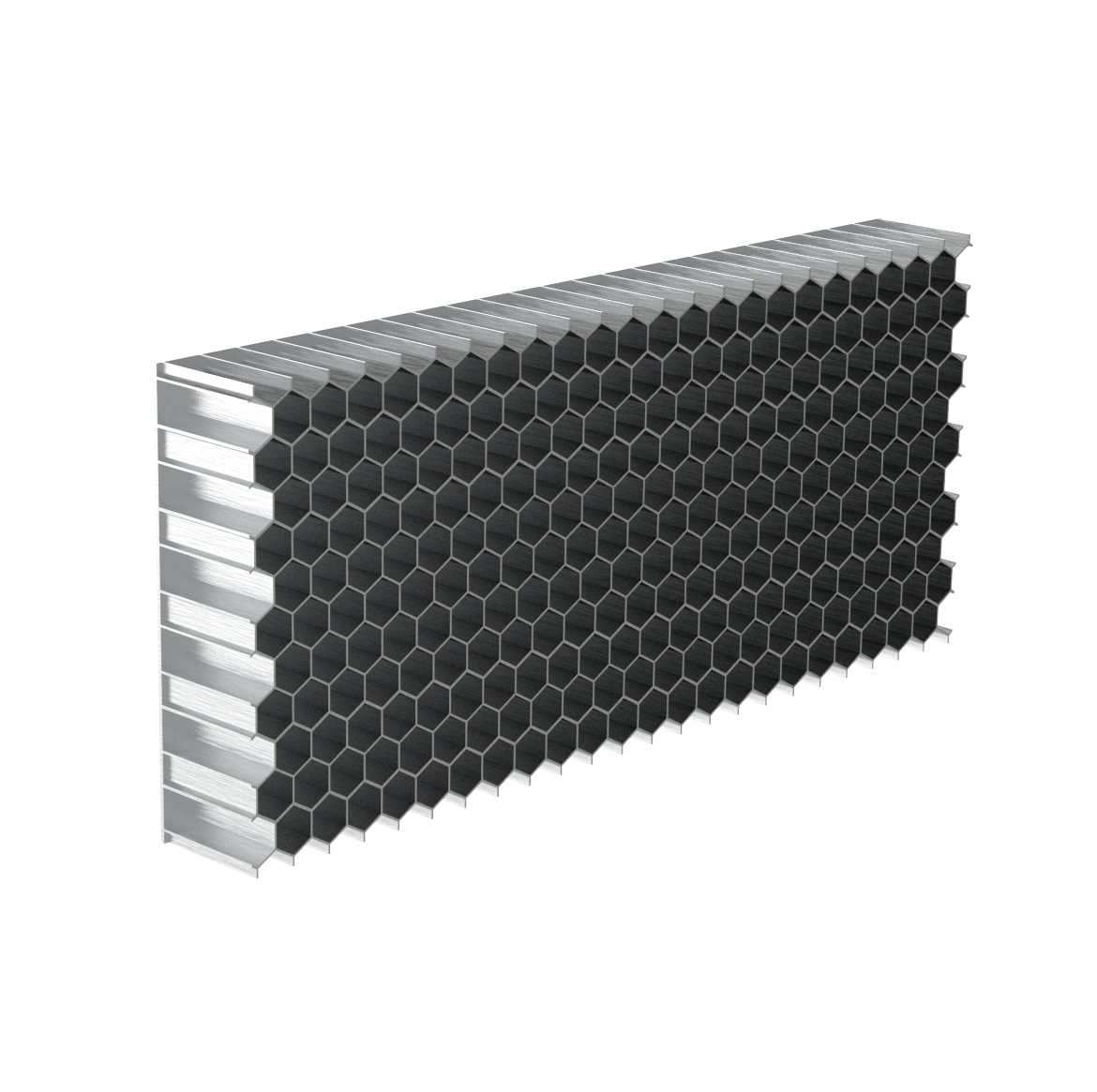

Honeycomb

The hexagonal shape of each cell in a honeycomb is the result of a clever design choice. Scientific research shows that this shape provides the ideal balance between maximum storage space as well as minimal material waste. In addition, the bees make optimal use of each piece of wax, creating a strong, durable and at the same time lightweight structure. The walls between the cells are also incredibly thin. The bee thus demonstrates its ingenious architecture.

For these reasons, the honeycomb is an inspiration for innovation and sustainability.

Honeycomb panels

Because of its similarity to the honeycomb of bees, scientists discovered that the hexagonal structure has many advantages. Among other things, it offers efficient use of space and great mechanical potential.

In 1945, they produced the first all-aluminium sandwich panel by gluing the honeycomb to panels. Since then, they have made different types of honeycomb structures from various materials.

Honeycomb structures attract a lot of attention because of their excellent energy absorption properties, light weight and cost savings. They find application not only in trains, cars and subways, but also in aircraft, ships and spacecraft, and so on.

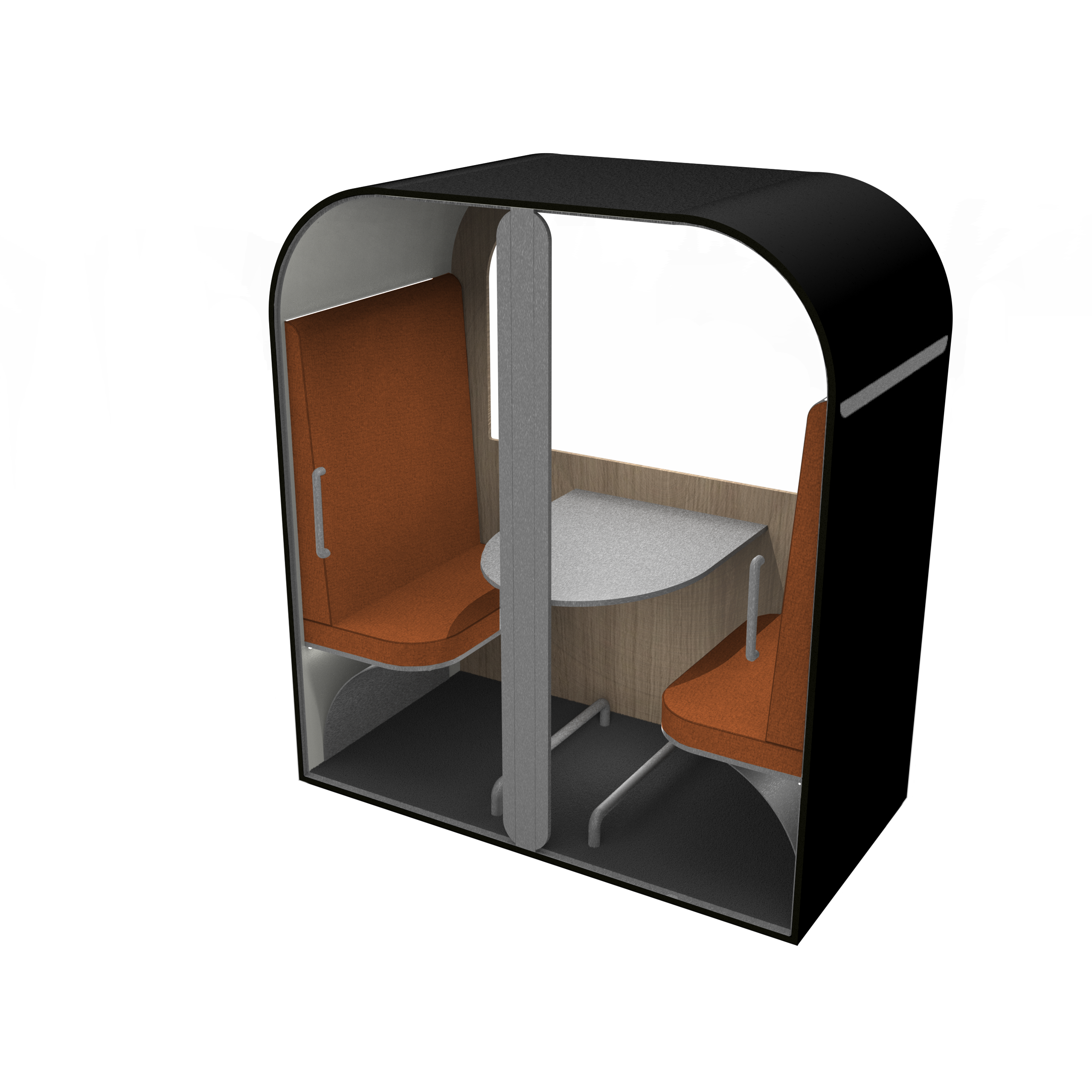

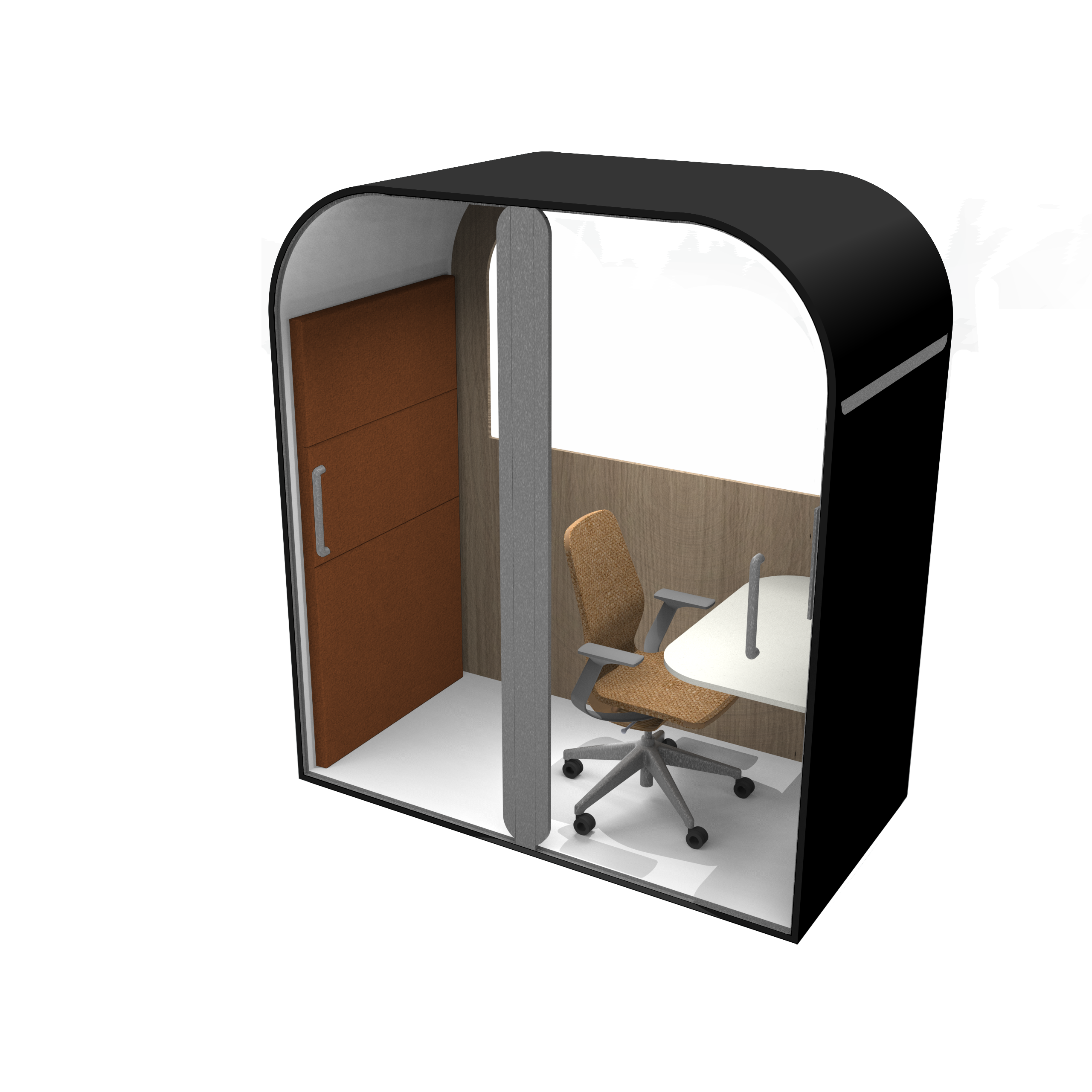

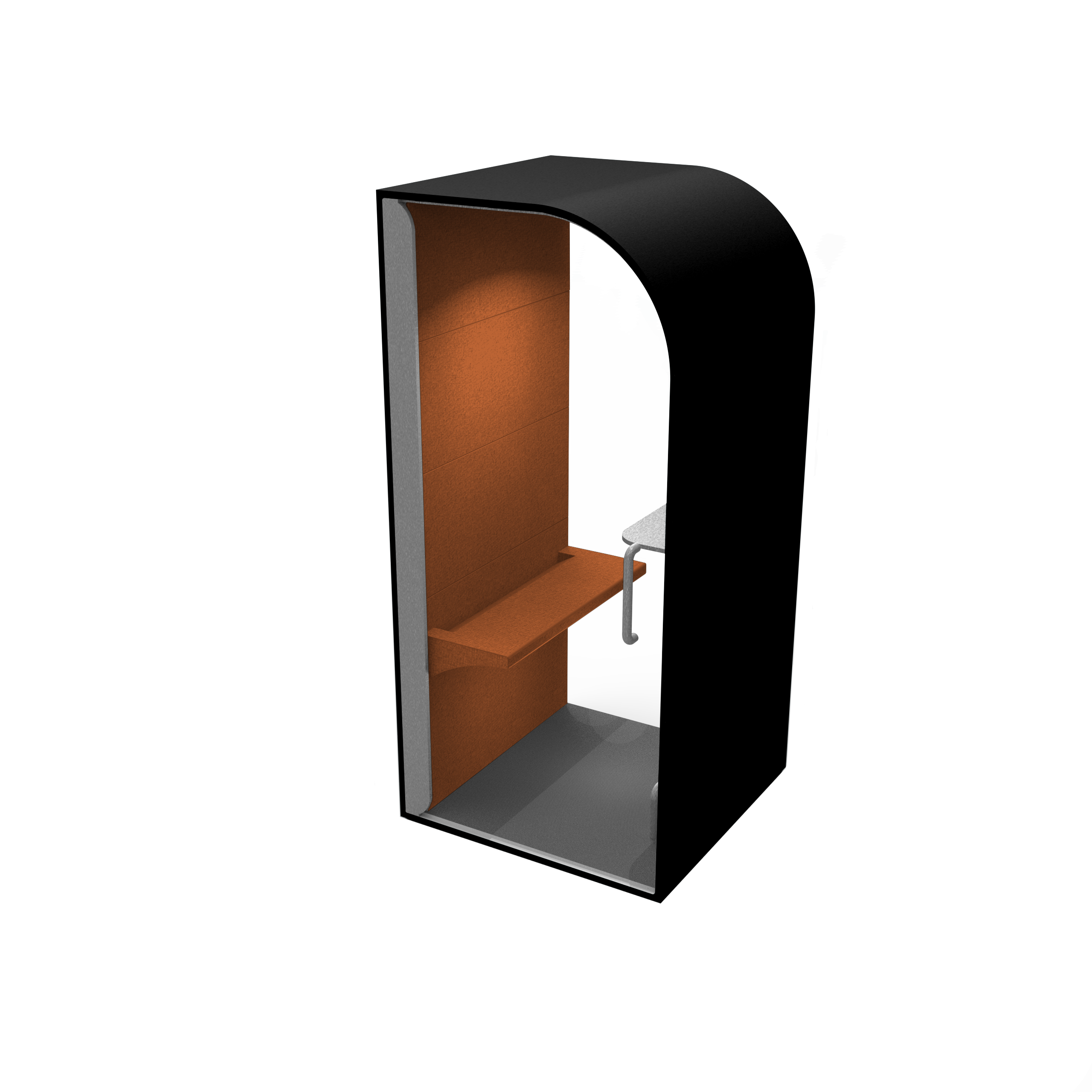

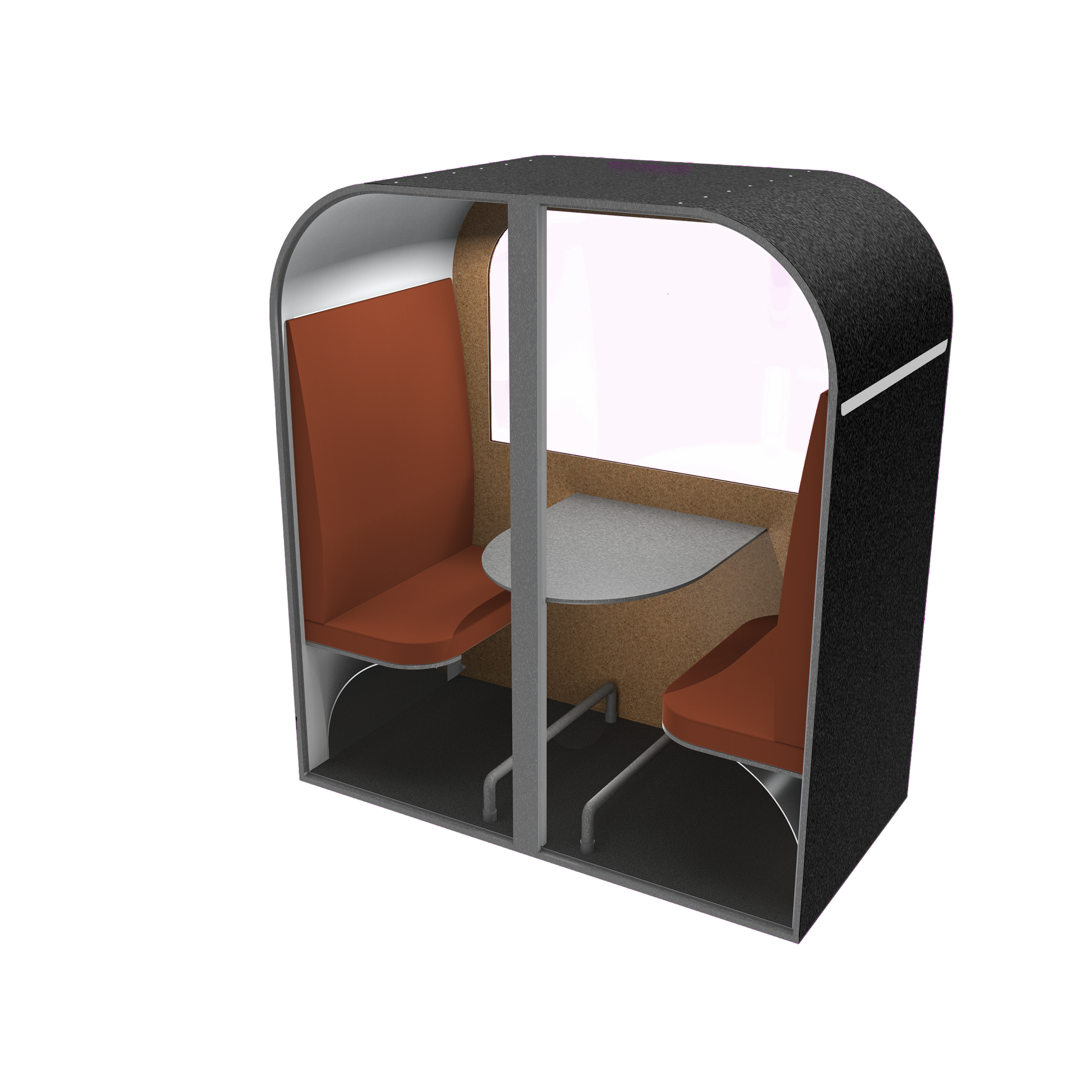

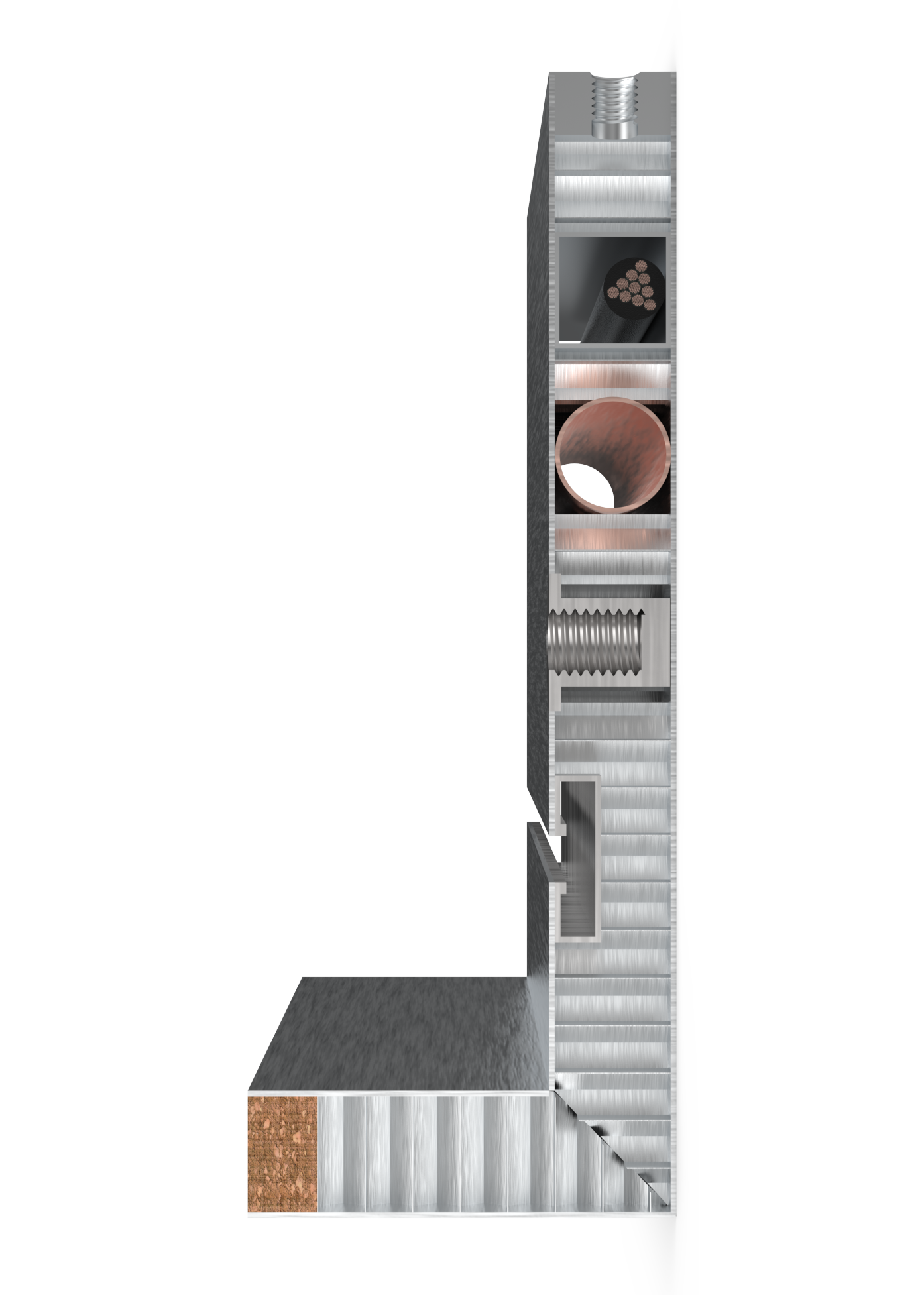

SMRTCOMB®

The above technology inspired us to develop SMRTCOMB®. It allows us to manufacture lightweight but extremely robust work spaces like the Cabb-in that are therefore easy to transport and assemble.

We combine not only the unique physical properties of the honeycomb (the core structure that consists of more than 99% air) but also other material structures that add additional functionalities in the material.

This creates an all-in-one Plug & Play system. This approach creates a flexible and durable base that also easily adapts to changing needs.

Tap into the power

Honeycomb panels are a versatile material with exceptional strength and durability. At the same time, they reduce weight. Their flexibility also makes them ideal for innovative architectural designs. They are used in many places around us, especially when performance is important, while the material itself does not stand out.

The panels are used because of their excellent properties: heat resistance, reduction in weight and fuel consumption, and high strength and stiffness while remaining lightweight.

Finally, we use SMRTCOMB® not only for Cabb-ins, but also for our customers in the train industry, where there are high user demands.